S7 200 Smart Plcth Io Ao Ith Ooooo Ooooo

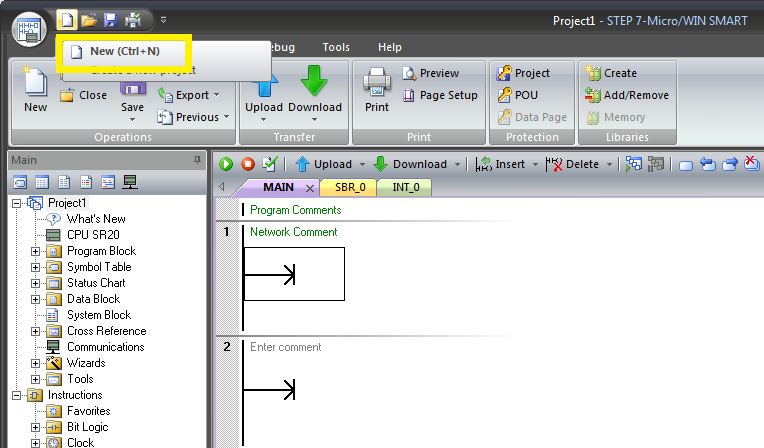

S7 200 Smart Plc Accessing Pdf Programmable Logic Controller Information Age Compact design, low cost, and a powerful instruction set make the s7‑200 smart a perfect solution for controlling small applications. the wide variety of s7‑200 smart models and the windows based programming tool give you the flexibility you need to solve your automation problems. This tutorial gives you step by step instructions on how to use a siemens s7 200 smart plc to control factory i o. connect the plc to the network. open the communications dialog in step 7 micro win smart. click on find cpus. from the list of available devices on the network highlight the one you want to use and click on ok.

Setting Up S7 200 Smart Factory I O Connect s7 200 smart plc to factory i o. factory io download – a 3d factory simulation software for learning automation technologies. factory i o supported the driver to connect to the device from allen bradley, schneider, siemens and other devices using modbus, opc…. Great for learning plc programming, testing logic, and simulating real world factory systems! 🔹 what you’ll see: s7 200 smart plc in action factory i o simulation realistic i o testing. Track the status of your support request online. an overview of your request can be found here: in order to protect technical infrastructures, systems, machines and networks against cyber threats, it is necessary to implement – and continuously maintain – a holistic, state of the art it security concept. This video demonstrates how to communicate siemens s7200 smart with factory io. factory io is a advanced software which is used for plc simulation.

Siemens S7 200 Smart 1ao Module At 8770 Piece Siemens Plc In Anand Id 2853773683112 Track the status of your support request online. an overview of your request can be found here: in order to protect technical infrastructures, systems, machines and networks against cyber threats, it is necessary to implement – and continuously maintain – a holistic, state of the art it security concept. This video demonstrates how to communicate siemens s7200 smart with factory io. factory io is a advanced software which is used for plc simulation. This case mainly explains the modbus rtu parameter configuration connection routine of the serial io series device (this time as a slave device) and the siemens plc s7 200smart (hereinafter referred to as siemens plc, this time as the host device). Compact design, low cost, and a powerful instruction set make the s7200 smart a perfect solution for controlling small applications. the wide variety of s7 200 smart models and the windows based programming tool give you the flexibility you need to solve your automation problems. This document takes s7 1500 as an io controller as an example to illustrate the configuration steps for s7 200 smart as an intelligent device to perform profinet io communication with other io controllers other than s7 200 smart. This driver provides an ethernet connection to siemens s7 200, s7 200 smart, s7 300 or s7 400 plc. configuration about analog values you should be aware of how floating and integer values are exchanged between factory i o and the plc.

Plc S7 200 Smart Create Example Program For Traffic Light 47 Off This case mainly explains the modbus rtu parameter configuration connection routine of the serial io series device (this time as a slave device) and the siemens plc s7 200smart (hereinafter referred to as siemens plc, this time as the host device). Compact design, low cost, and a powerful instruction set make the s7200 smart a perfect solution for controlling small applications. the wide variety of s7 200 smart models and the windows based programming tool give you the flexibility you need to solve your automation problems. This document takes s7 1500 as an io controller as an example to illustrate the configuration steps for s7 200 smart as an intelligent device to perform profinet io communication with other io controllers other than s7 200 smart. This driver provides an ethernet connection to siemens s7 200, s7 200 smart, s7 300 or s7 400 plc. configuration about analog values you should be aware of how floating and integer values are exchanged between factory i o and the plc.

Comments are closed.